ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

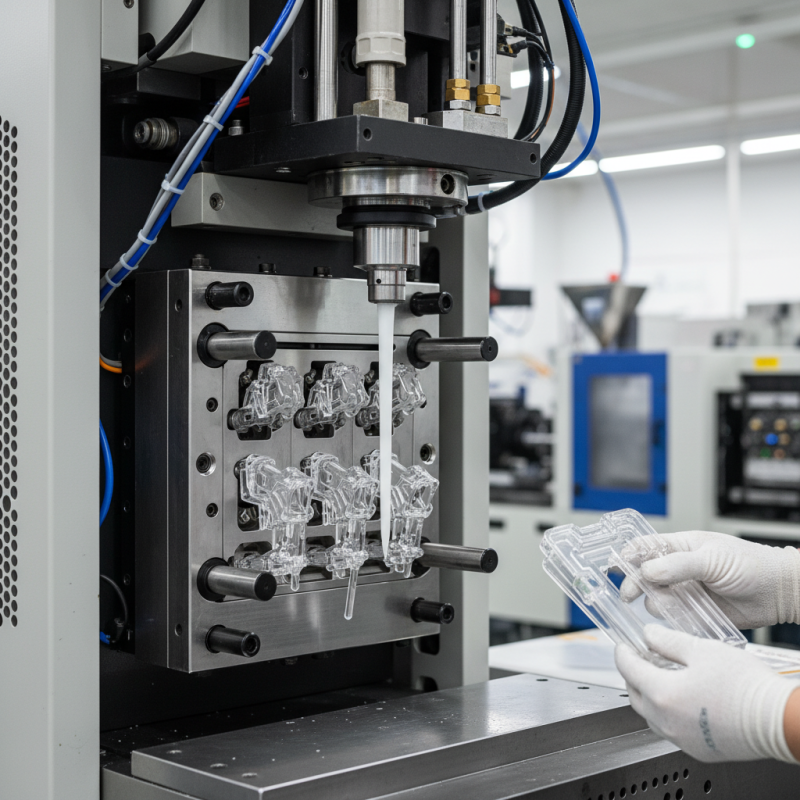

learn moreEssential Tips for Mastering Plastic Injection Mold Techniques?

In the world of manufacturing, mastering Plastic Injection Mold techniques is crucial. Tim Johnson, a renowned expert in the plastic injection mold industry, once stated, "Precision in mold design dictates product quality." This emphasizes the importance of understanding every aspect of plastic injection molding.

Injecting plastic into molds may seem straightforward. However, achieving perfection is often elusive. Many beginners struggle with issues like air bubbles and uneven fill. These problems highlight the complexity of the process. Each step, from choosing the right materials to adjusting temperature, requires careful consideration. Attention to detail can make a significant difference in the final product.

Moreover, the industry often overlooks the necessity of continuous learning. Experienced professionals may become complacent, missing out on new techniques and tools. Engaging with the latest innovations is vital. Embracing challenges and reflecting on past mistakes can lead to improved skills and outcomes in plastic injection mold production. A commitment to refining techniques is essential for any serious player in this field.

Essential Principles of Plastic Injection Molding Techniques

When mastering plastic injection molding techniques, understanding essential principles is crucial. The process begins with selecting the right materials. Materials vary in properties, affecting the final product. Not all plastics are suitable for every application. Experimenting with different combinations can lead to innovative solutions.

Temperature control is another key principle. Too high or too low temperatures can ruin your mold. Finding the ideal temperature is a trial-and-error process. Insufficient heating can cause defects, while overheating can lead to degradation. Monitoring temperatures meticulously ensures quality.

The design of molds can often present challenges. Complex designs may seem appealing but can complicate manufacturing. Sometimes, simplicity leads to better outcomes. An effective mold design streamlines production and minimizes waste. Reflecting on past mistakes helps improve future designs and processes. This journey requires patience and a willingness to learn. Embracing imperfections can foster growth and mastery in this intricate field.

Key Parameters Impacting Mold Design and Production Efficiency

When mastering plastic injection mold techniques, understanding key parameters is critical. The mold design heavily influences both quality and efficiency. For instance, wall thickness affects cooling time and part strength. A consistent wall thickness ensures even cooling, which reduces warping. However, achieving uniformity can be tricky and requires precise control.

Another important factor is the choice of materials. The right material enhances durability and processability. Each material has unique thermal properties that affect the injection process. Some materials may degrade if processed at incorrect temperatures. This can lead to wasted resources and production delays. Reflecting on material choices is essential for improving outcomes.

Cycle time is also a parameter that impacts production efficiency. Faster cycles boost productivity, but this must be balanced with part quality. Shortening a cycle can lead to defects. Finding the right speed requires careful testing and adjustments. Continuous monitoring of cycle times can reveal hidden inefficiencies. These reflect the ongoing challenges in the molding process and highlight areas for improvement.

Material Selection: Balancing Performance and Cost in Injection Molding

Material selection in injection molding is crucial. It affects both performance and cost. Choosing the right resin can enhance product durability and aesthetics. However, balancing these factors can be challenging.

One tip is to consider the end-use of the product. Different applications require different properties. For example, a part exposed to high temperatures may need a specialized resin. Think about the environment and wear it will face.

Another important aspect is to evaluate cost versus benefits. Some materials might be cheaper upfront but lead to higher maintenance costs later. Analyze the entire lifecycle of the product. Make sure it fits your budget while meeting performance standards.

Don’t overlook the importance of material testing. Prototype parts with different resins before committing. This step can reveal potential weaknesses. Evaluating performance through real-world scenarios can be eye-opening. Make adjustments based on testing outcomes.

Common Challenges in Injection Molding and Their Practical Solutions

Injection molding is a complex process. Common challenges can arise during production. These issues can affect quality and efficiency. Understanding them is essential for success.

One frequent problem is warping. It can occur due to uneven cooling. To combat this, ensure consistent temperature control. Adjusting cooling rates can significantly reduce warping. Check mold design for possible pinch points. These can create localized stresses, leading to defects.

Another issue is improper material flow. Poor flow can cause incomplete parts. To resolve this, analyze the mold temperature and pressure settings. Increasing the injection speed may help. But be cautious; too fast can induce air traps. Consider running a trial with adjustments to find the sweet spot.

Regular maintenance is vital. Worn-out molds can lead to defects over time. Inspect molds frequently for wear and tear. This proactive approach can prevent bigger problems down the line. Always document the process and changes made. Reflecting on these aspects can enhance your molding techniques.

Innovative Technologies Enhancing Plastic Injection Mold Processes

Innovative technologies are revolutionizing plastic injection mold processes. These advancements lead to better efficiency and product quality. One such technology is the use of 3D printing in mold design. This method allows for rapid prototyping and modifications. Designers can test concepts faster than traditional methods. The speed and flexibility offered by 3D printing can reduce development time significantly.

Another key innovation is smart sensors integrated into molds. These sensors monitor temperature and pressure in real-time. They help predict potential issues before they escalate. However, not every facility has adopted this technology yet. Some struggle with implementation due to cost or training needs. This creates a gap in efficiency that some companies may overlook. Embracing these technologies is critical, but it requires commitment and resources.

Furthermore, new materials for molds are emerging. These materials can withstand higher temperatures and pressures, enhancing durability. However, the transition to such materials may come with challenges. Teams may need to retrain to understand new specifications. Each step towards innovation isn't without hurdles. Reflecting on these challenges is important for continuous improvement in processes.

Essential Tips for Mastering Plastic Injection Mold Techniques

This chart illustrates the percentage impact of various key factors on the efficiency of plastic injection molding processes. Understanding these elements can help in mastering the techniques required for effective mold production.