ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreHow to Effectively Utilize a Horizontal Form Fill Seal Machine for Your Production Needs

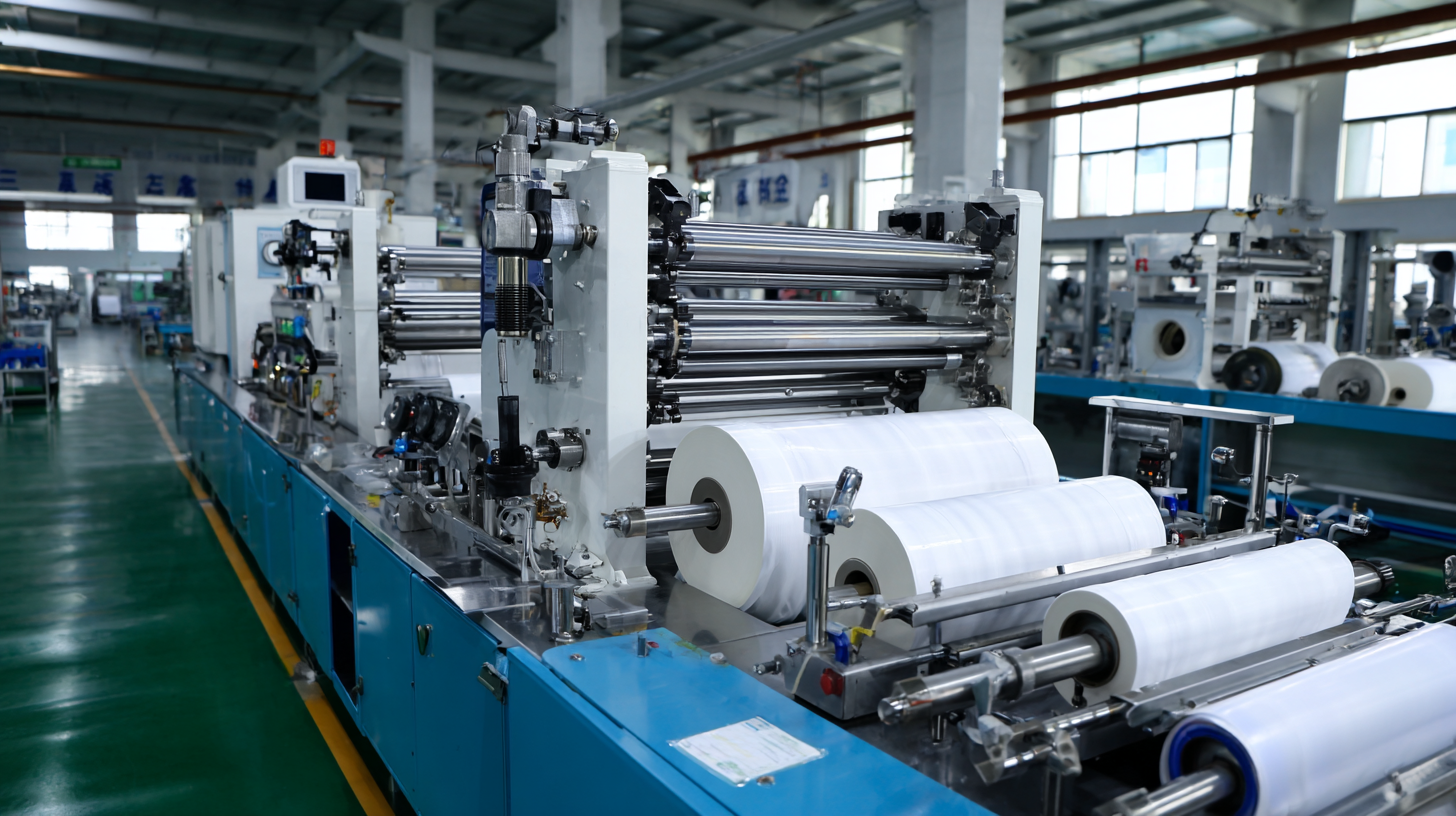

In today's fast-paced manufacturing landscape, the efficient use of a Horizontal Form Fill Seal Machine is crucial for optimizing production processes. This versatile equipment plays a significant role in packaging industries by automatically forming, filling, and sealing pouches, thereby streamlining operations and improving productivity. Understanding how to effectively utilize this machine can lead to significant cost savings and enhanced product quality. In this guide, we will explore key techniques and best practices to maximize the capabilities of a Horizontal Form Fill Seal Machine, ensuring that your production needs are met while maintaining the highest standards of efficiency and safety. Whether you are new to this technology or looking to refine your current processes, this comprehensive approach will equip you with the knowledge required to leverage this powerful tool in your production line.

Choosing the Right Horizontal Form Fill Seal Machine for Your Products

Choosing the right horizontal form fill seal (HFFS) machine is crucial for optimizing your production line’s efficiency and product quality. With the global packaging machinery market expected to reach approximately $50 billion by 2025, selecting the correct equipment can determine not only output but also competitive edge. HFFS machines are ideal for packaging a variety of products, from food items to pharmaceuticals, and should be chosen based on specific product characteristics, such as granule size, viscosity, and required shelf life. According to a recent report by Smithers Pira, nearly 60% of packaging operations rely on automated forms like HFFS for their speed and versatility.

When selecting an HFFS machine, operators should consider key specifications including machine speed, seal type, and material compatibility. Data from a survey conducted by PMMI, The Association for Packaging and Processing Technologies, reveals that over 70% of manufacturers prioritize machine flexibility and the ability to handle multiple pack formats. This is particularly relevant in markets where consumer demands shift quickly, requiring packaging solutions that can adapt without significant downtime. Ensuring that your chosen HFFS machine aligns with both present and future production needs can significantly impact your operational efficiency and product marketability.

Essential Setup Steps for Optimal Performance in HFFS Machines

Setting up a Horizontal Form Fill Seal (HFFS) machine correctly is crucial for achieving optimal performance in your production line. The first step involves ensuring that the machine is properly calibrated. This includes aligning the forming, filling, and sealing components accurately. Any misalignment can lead to product waste or machine downtime.

Tip: Before starting production, conduct a dry run to test the setup without materials. This will allow you to identify potential adjustments without risking actual product loss.

Next, selecting the right film material plays a pivotal role in the efficiency of your HFFS machine. It's essential to choose a film that matches your product’s requirements, including barrier properties and sealing temperatures. Using incompatible materials can compromise the integrity of your packages.

Tip: Experiment with different film types during the initial setup phase to determine which material yields the best results in terms of sealing and product protection.

Lastly, consistently monitoring machine performance during operation allows you to make real-time adjustments. Incorporating feedback mechanisms can help in identifying issues before they escalate, ensuring smooth operation and minimizing production interruptions.

How to Effectively Utilize a Horizontal Form Fill Seal Machine for Your Production Needs - Essential Setup Steps for Optimal Performance in HFFS Machines

| Step | Description | Importance |

|---|---|---|

| 1 | Ensure machine installation is on a level surface. | Prevents operational issues and ensures even filling. |

| 2 | Calibrate sealing temperature based on material type. | Ensures optimal seal integrity and product shelf life. |

| 3 | Conduct trial runs to assess fill accuracy. | Identifies potential issues before full production. |

| 4 | Regularly maintain and clean machine components. | Prevents breakdowns and extends machinery lifespan. |

| 5 | Train operators on machine functions and safety. | Ensures safe and efficient operation. |

Maintenance Best Practices to Extend the Lifespan of Your HFFS Equipment

To effectively extend the lifespan of your Horizontal Form Fill Seal (HFFS) machine, regular maintenance is crucial. Implementing a systematic maintenance schedule can significantly reduce downtime and enhance operational efficiency. Start by frequently checking critical components such as sealing bars and film tension systems to ensure they are functioning optimally. Cleaning the machine regularly will prevent the buildup of contaminants that can lead to malfunctions. Additionally, using high-quality packaging materials will minimize wear and tear on the equipment, thereby prolonging its performance.

As the packaging industry evolves with trends such as whole bird packaging and lower-calorie options, the importance of properly maintained HFFS machines cannot be overstated. Equipment like HFFS systems must adapt to new packaging requirements efficiently. Regular updates to the machine's software and hardware capabilities can also be beneficial in responding to market demands. Staying informed about industry changes, such as regulatory impacts on HFSS products, enables operators to adjust their processes accordingly, ensuring that they can maintain consistency and quality in their production lines.

Troubleshooting Common Issues in Horizontal Form Fill Seal Operations

When operating a Horizontal Form Fill Seal (HFFS) machine, it is essential to be aware of common issues that can arise during production. One of the most frequent problems is poor sealing, often caused by improper temperature settings or insufficient sealing pressure. To troubleshoot this issue, operators should regularly check the machine’s temperature settings and adjust them according to the materials being used. Additionally, ensuring that the seal rollers and sealing surfaces are clean and free of debris can significantly improve sealing quality.

Another common concern is product breakage or misalignment within the machine. This can occur due to incorrect product feed or variations in product dimensions. To address this, operators should frequently inspect product guides and adjust them to secure proper alignment. Regular maintenance of the conveyor systems and ensuring a consistent flow of products can also mitigate these issues. Addressing these common problems promptly not only enhances production efficiency but also ensures the quality of the packaged products.

Maximizing Efficiency: Tips for Streamlining Your Production Line with HFFS Machines

Streamlining your production line with a Horizontal Form Fill Seal (HFFS) machine involves several key practices that maximize efficiency. First, ensure that your production layout is optimized for the flow of materials. Ideally, the HFFS machine should be positioned near the raw material supply and downstream packaging stations to reduce handling time and minimize delays. Additionally, keeping the work area organized and free of clutter can lead to smoother operation and less downtime during transitions between product runs.

Another crucial factor is the regular maintenance of the HFFS machine. Routine checks and preventive maintenance help avoid unexpected breakdowns, which can disrupt the entire production line. Operators should be well-trained to identify and troubleshoot minor issues before they escalate. It is also advisable to implement a feedback loop, where operators can report on the machine's performance, suggesting adjustments or updates that might enhance efficiency. By engaging everyone involved in the production process, you create a collaborative atmosphere that encourages continuous improvement and adherence to best practices.

Production Efficiency of Horizontal Form Fill Seal Machines

This chart illustrates the production efficiency of Horizontal Form Fill Seal Machines across four quarters. As seen, there is a steady increase in units produced, highlighting the potential for maximizing production efficiency.

Related Posts

-

Innovative Approaches to Packaging Machines in 2025 Trends and Eco-Friendly Alternatives

-

Ultimate Guide to Choosing the Best Packaging Equipment: Insights and Data for Optimal Efficiency

-

Ultimate Guide to Choosing the Best Bagging Equipment for Global Procurement Success

-

Top 10 Case Packing Equipment Manufacturers from China at the 137th Canton Fair

-

Understanding the Functionality of Form Fill And Seal Machines

-

Surviving Tariff Hurdles: How China's 'Best Vertical Form Fill Seal' Equipment Thrives Globally