ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreTop Benefits of Using Horizontal Form Fill Seal Machines in Packaging Industry

In the rapidly evolving landscape of the packaging industry, efficiency and precision are paramount. One of the key innovations contributing to this advancement is the Horizontal Form Fill Seal Machine. These machines are revolutionizing the way products are packaged, offering a multitude of benefits that enhance operational efficiency and reduce waste. Designed to streamline the packaging process, horizontal form fill seal machines automatically create, fill, and seal packages in a continuous operation, minimizing the need for manual labor and reducing production time.

The versatility of Horizontal Form Fill Seal Machines makes them suitable for packaging a wide array of products, from food items to pharmaceuticals. Their ability to operate at high speeds while maintaining consistent quality ensures that manufacturers can meet increasing consumer demands without compromising on product integrity. Furthermore, these machines are equipped to handle various materials, allowing companies to explore eco-friendly packaging options that align with modern sustainability goals. By investing in horizontal form fill seal technology, businesses not only improve their productivity but also enhance their competitive edge within the packaging sector.

Understanding Horizontal Form Fill Seal Machines: An Overview

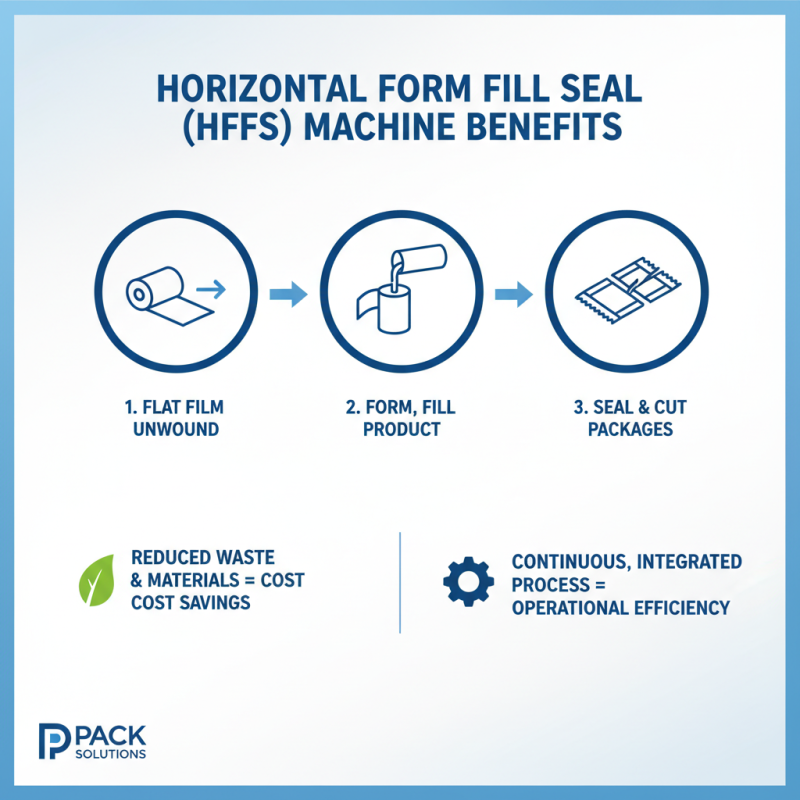

Horizontal Form Fill Seal (HFFS) machines have become essential in the packaging industry, facilitating the efficient and economical packaging of a wide range of products. These machines operate by forming a tube from flat film, filling it with product, and sealing it in a continuous motion. This streamlined process not only enhances productivity but also reduces labor costs, making it a preferred choice for manufacturers looking to optimize their packaging operations.

Understanding how HFFS machines work reveals their versatility and adaptability. They can handle various materials, accommodating liquid, solid, and even granular products. The flexibility in packaging formats—ranging from pouches to bags—makes HFFS machines suitable for multiple industries, including food, pharmaceuticals, and personal care products. Additionally, advancements in technology have led to features such as automated controls and easy setup processes, enabling manufacturers to quickly switch between different product lines without significant downtime.

The benefits of using HFFS machines extend beyond efficiency. The machines often include features that ensure product safety and integrity, like airtight seals that help preserve freshness and prevent contamination. As the demand for packaging solutions that are both efficient and sustainable grows, HFFS machines increasingly incorporate eco-friendly materials, making them a forward-thinking choice in a competitive market.

Key Features of Horizontal Form Fill Seal Machines in Packaging

Horizontal Form Fill Seal (HFFS) machines play a pivotal role in the packaging industry, offering a range of key features that enhance operational efficiency. One of the most significant attributes of HFFS machines is their ability to create packaging solutions directly from a flat film, which can be seamlessly transformed into a tube, filled with the product, and then sealed in a continuous process. This integration reduces the need for separate packaging materials and minimizes waste, ultimately leading to cost savings for manufacturers.

Another noteworthy feature of HFFS machines is their flexibility in accommodating various products and packaging sizes. These machines can be easily adjusted to handle both solid and liquid items, making them suitable for diverse applications—from food and beverages to pharmaceuticals. Additionally, HFFS machines are equipped with advanced control systems that ensure precise filling and sealing processes, enhancing product integrity and shelf life. The automation involved also allows for higher production speeds, improving overall productivity while maintaining consistent quality in the finished packages.

Efficiency Gains from Using Horizontal Form Fill Seal Machines

Horizontal form fill seal (HFFS) machines have revolutionized the packaging industry by significantly improving efficiency across various production lines. The streamlined process begins with a roll of flexible packaging material, which is formed into a tube, filled with the product, and then sealed, all in a continuous motion. This integration minimizes the number of operators needed and reduces the time spent on changeovers between different products or formats, thus optimizing workflow. As a result, manufacturers can increase output without compromising on quality.

Additionally, HFFS machines allow for precise control over the filling process, which is crucial for maintaining consistent product quantities and reducing waste. These machines often come equipped with advanced sensors and automation features that monitor fill levels and detect any deviations in real-time, ensuring that production runs smoothly. The ability to quickly change sizes and formats also enhances flexibility, making it easier to meet varying consumer demands and market trends without extensive downtime. Overall, the adoption of HFFS technology not only amplifies productivity but also supports manufacturers in achieving a more responsive and adaptable packaging process.

Cost-Effectiveness of Horizontal Form Fill Seal Technology

Horizontal Form Fill Seal (HFFS) technology has revolutionized the packaging industry, offering significant cost advantages that contribute to both operational efficiency and profitability. One of the key benefits of HFFS machines is their ability to streamline the packaging process. By consolidating multiple steps—forming, filling, and sealing—into a single automated operation, businesses can reduce labor costs and minimize the need for manual intervention. This decreased reliance on human labor not only lowers operational expenses but also enhances overall productivity, allowing companies to reallocate resources to other critical areas of their operation.

Moreover, HFFS machines utilize materials more efficiently, reducing waste and optimizing packaging material costs. The precision of these machines ensures that the exact amount of product is used for each package, and the compact nature of horizontal formats allows for more effective use of packaging films. This capability not only leads to lower material expenditures but also reduces storage needs and transportation costs. Overall, the financial benefits of adopting HFFS technology make it a compelling choice for companies looking to enhance their bottom line while maintaining high standards of quality and performance in their packaging processes.

Applications of Horizontal Form Fill Seal Machines in Various Industries

Horizontal Form Fill Seal (HFFS) machines play a pivotal role in the packaging industry across various sectors due to their versatility and efficiency. One of the primary applications of HFFS machines is in the food industry, where they are utilized for packaging snacks, frozen meals, and dairy products. These machines efficiently create packaging that preserves freshness and extends shelf life, ensuring that products remain appealing to consumers. The ability to produce pouches of different sizes and shapes caters to the demands of various food items, from ready-to-eat meals to bulk snacks.

In addition to the food sector, HFFS machines are widely used in the pharmaceutical and healthcare industry. They package tablets, capsules, and blister packs with precision, maintaining strict hygiene standards while minimizing contamination risks. The automation of packaging processes enhances productivity and reduces labor costs, allowing manufacturers to focus on quality and innovation. Furthermore, these machines are increasingly employed in the cosmetic and personal care sectors for packaging items such as lotions, creams, and powders, showcasing their adaptability across industries. By streamlining packaging procedures, HFFS machines contribute to efficiency and consistency in product delivery, making them an indispensable resource in modern manufacturing.

Related Posts

-

Exploring Diverse Packaging Solutions: How to Choose the Right Fit for Your Global Procurement Needs

-

The Future of Packaging Solutions: Revolutionizing Production with the Best Pouch Filler

-

5 Key Reasons Flexible Packaging is Revolutionizing the Food Industry

-

Innovative Form Fill Seal Examples Transforming Packaging Solutions

-

Understanding the Functionality of Form Fill And Seal Machines

-

Exploring the Surge in Global Demand for Sachet Packaging at the 137th Canton Fair