ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more2026 Top Laser Cutting Machine Trends and Innovations?

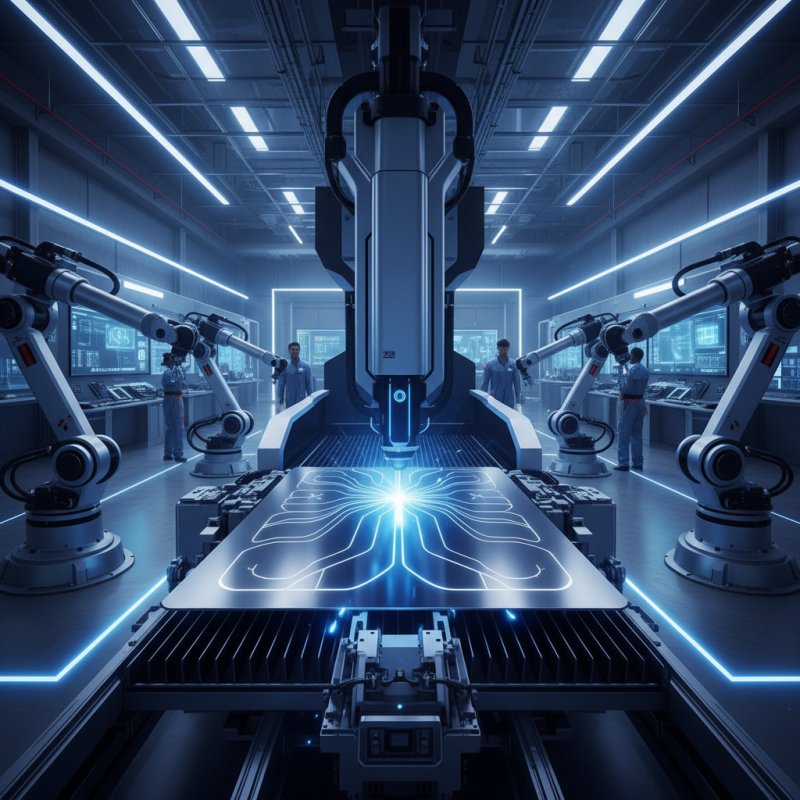

The landscape of manufacturing is evolving rapidly. One of the key players in this transformation is the laser cutting machine. These machines have gained immense popularity due to their precision and efficiency. In 2026, we will witness several trends that will shape their future.

Innovations in laser technology will enhance cutting speed and accuracy. Companies are increasingly seeking machines that provide cleaner cuts and faster turnaround times. This demand drives manufacturers to explore advanced materials and techniques. Laser systems are becoming more versatile, allowing for a broader range of applications.

Yet, challenges remain. Many users struggle to adopt these technologies fully. Training and maintenance can be obstacles. Embracing new innovations often requires changes in workflow and mindset. As we look ahead, it's vital to address these issues while embracing the exciting potential of laser cutting machine advancements.

2026 Advancements in Laser Cutting Technology

The year 2026 is set to bring significant advancements in laser cutting technology. As industries push for greater efficiency, innovations are emerging. One prominent trend is the integration of artificial intelligence. This technology enhances precision during cutting, significantly reducing waste. AI systems can analyze materials and adjust settings in real-time, creating more consistent results.

Another exciting development is the use of advanced optics. New lens designs improve focus and beam quality. This allows for cleaner cuts and faster processing times. However, there are challenges. The cost of these advanced optics can be prohibitive for smaller manufacturers. They must balance quality with their budget constraints.

Sustainability is also a key focus. Businesses are exploring eco-friendlier materials and processes. Often, this requires new techniques that may not yet be perfected. While the shift towards greener practices is essential, it can also complicate operations. Innovations in power efficiency and energy sources are necessary to meet these demands. The journey toward these advancements is ongoing and sometimes fraught with difficulties.

2026 Top Laser Cutting Machine Trends and Innovations

Emerging Materials for Laser Cutting Applications

Emerging materials are shaping the future of laser cutting applications. In 2026, we're noticing a significant shift toward more innovative substances. These materials are lightweight yet durable. They enhance performance and expand the possibilities for various industries.

For instance, advanced polymers are becoming more popular. These materials offer flexibility and resilience. Engineers are finding new techniques to manipulate these polymers under laser cutting. Recycling these materials is also a hot topic. Companies are looking for sustainable options that reduce waste. Metal composites are another emerging trend. They combine different metals to improve strength and machinability.

Some challenges remain. Not all new materials are compatible with existing laser cutting technology. Manufacturers need to adapt their machines and processes. This requires experimentation and innovation. The future is exciting but uncertain. The quest for perfect materials continues. Each step forward brings lessons learned and areas for improvement.

Integration of AI and Automation in Laser Cutting Machines

The integration of AI and automation in laser cutting machines is revolutionizing the industry. Manufacturers are increasingly adopting smart technologies to enhance productivity. AI algorithms optimize cutting paths and reduce preparation time, allowing for greater efficiency. This level of automation can decrease human error, but it also raises concerns about workforce displacement.

Automation brings speed and precision, yet it can complicate maintenance. Machines become advanced, requiring specialized skills for repairs. Not all technicians are prepared for this shift. Firms may need to invest in training programs. Current employees might resist changes, fearing obsolescence. Balancing innovation with human skills is crucial.

Another significant aspect is data utilization. AI systems analyze variables continuously, adjusting operations in real time. This leads to improved production quality. However, over-reliance on data can stifle creativity. Workers may follow AI recommendations too strictly. Creativity in design could be sacrificed for efficiency. Striking a balance is essential for sustainable growth in the laser cutting sector.

Sustainability Trends in Laser Cutting Processes

Sustainability is reshaping laser cutting processes. Eco-friendly practices are now a priority. In laser cutting, energy efficiency matters. According to a recent industry report, laser cutting machines can reduce energy consumption by up to 50% compared to traditional methods. This shift not only lowers operational costs but also minimizes carbon footprints.

The materials used in laser cutting are also evolving. There is a growing trend toward utilizing recyclable materials. Many manufacturers are experimenting with biodegradable alternatives. This approach can significantly impact waste management in the cutting industry. A study shows that about 30% of materials used in laser cutting can now be recycled, increasing sustainability.

Challenges remain. Not all laser cutting processes are equally green. Some methods still rely heavily on harmful gases and chemicals. Additionally, the disposal of laser-cut waste poses environmental risks. Innovators must address these issues to advance sustainability fully. The future of laser cutting lies in continuous improvement and reflection on its environmental impact.

Future Challenges and Opportunities in Laser Cutting Industry

The laser cutting industry faces several challenges and opportunities as it evolves. According to a recent report, the global laser cutting market is projected to grow at a CAGR of 7.5% until 2026. This growth is driven by advancements in technology and increasing demand for precision manufacturing. However, companies must adapt to the rapidly changing landscape. Adopting new technologies can require significant investment. Many firms struggle to balance innovation with cost management.

Sustainability is another pressing issue within laser cutting. With rising concerns about environmental impact, manufacturers are called to reduce waste. Some companies are exploring eco-friendly materials and energy-efficient machines. This presents an opportunity to lead in sustainable practices. However, transitioning to greener processes can be complex and resource-intensive. Firms must weigh the long-term benefits against short-term inconveniences.

Employee training is critical as well. The adoption of advanced systems means technical skills are essential. Many workers lack the expertise to operate and maintain new machines. Companies might face productivity dips during training periods. Addressing these skills gaps is vital for future success in the industry. Opportunities abound for those who can adapt and innovate. The journey is fraught with challenges that deserve attention and strategic planning.