2026 Best Butterfly Valves for Sale Reviews and Buying Guide?

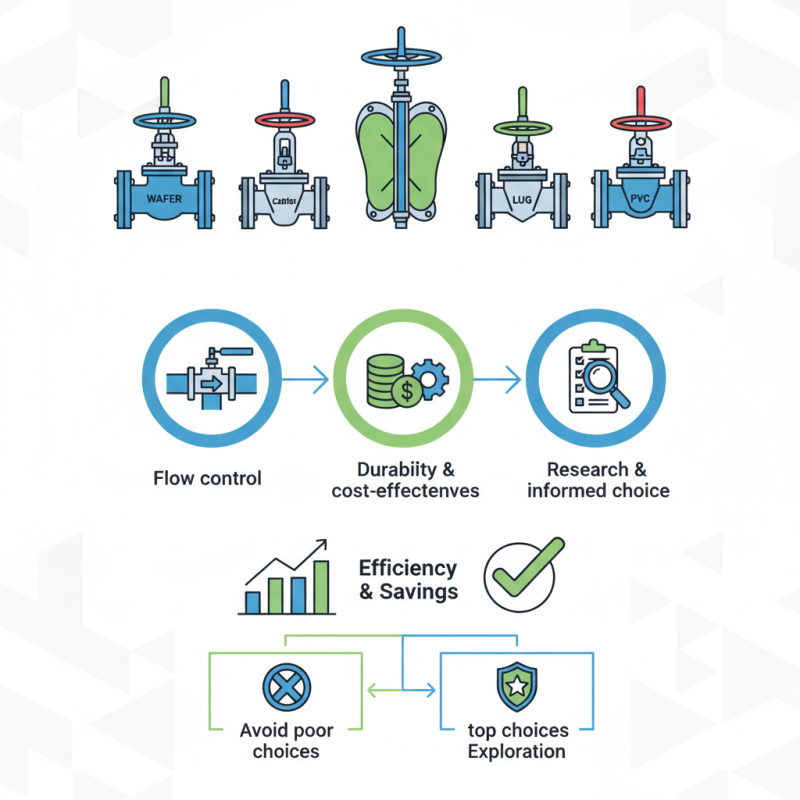

When searching for the best butterfly valves for sale, the options can be overwhelming. These valves are essential in controlling flow in various systems. With different materials, sizes, and designs available, it's crucial to make an informed choice.

Consider the specific needs of your project. Some valves may offer better durability, while others could be more cost-effective. It’s important to analyze your requirements carefully. A high-quality butterfly valve can lead to long-term savings and efficiency.

However, not all products are equal. Misleading marketing can lead to poor choices. Take time to read reviews and understand the strengths and weaknesses of each option. This guide aims to navigate through the complexities of butterfly valves for sale. Let’s explore the top choices together.

Overview of Butterfly Valves: Types and Applications

Butterfly valves are crucial in controlling flow in various industries. These valves are designed with a circular disc that pivots to open or close the passage. They offer different types suitable for various applications, including high-pressure and low-pressure systems. According to a recent industry report, the global butterfly valve market is projected to reach $8 billion by 2026, reflecting a growing demand in sectors such as oil and gas, water treatment, and HVAC.

Common types include resilient seated, high-performance, and double-offset butterfly valves. Each type serves specific needs. For instance, high-performance valves are ideal for high-pressure applications. Meanwhile, resilient-seated valves work well for low-pressure systems. The choice depends on the operational environment and fluid types involved.

Tips: Always consider the system's pressure and temperature when selecting a valve. It's essential to review installation requirements. Ensure that the valve can handle the medium's characteristics, including corrosiveness. Remember, a poorly selected valve can lead to leaks and inefficient operations. Always conduct thorough research before making a purchase decision.

Key Features to Consider When Buying Butterfly Valves

When purchasing a butterfly valve, consider the material. Common options include PVC, stainless steel, and cast iron. The choice affects durability and resistance to corrosion. PVC is lightweight but may not withstand high temperatures. Stainless steel is robust, often used in industrial applications. Cast iron can handle heavy loads but might rust without proper treatment.

Next, think about the size and pressure rating. Mismatched sizes can lead to leaks. It's crucial to check pipe diameters and valve dimensions. Pressure rating is equally important, as inadequate ratings can cause failures. Look for valves that meet your operational requirements.

Lastly, consider the design. A basic wafer-style valve can save space. A lug-style valve offers better mounting options. Each design has pros and cons. Some users find operation challenging when not familiar with specific designs. Make sure to weigh the features according to your needs and circumstances. There are always details that could be missed, making careful consideration essential.

2026 Best Butterfly Valves for Sale Reviews and Buying Guide

| Model | Size (inches) | Material | Max Pressure (psi) | Temperature Range (°F) | Price ($) |

| Model A | 2 | Cast Iron | 150 | 32 to 180 | 50 |

| Model B | 3 | PVC | 70 | 33 to 140 | 30 |

| Model C | 4 | Stainless Steel | 200 | -20 to 250 | 120 |

| Model D | 6 | Aluminum | 300 | 0 to 200 | 250 |

| Model E | 8 | Bronze | 150 | 32 to 180 | 200 |

Top 2026 Butterfly Valves: Reviews of Leading Models

When it comes to choosing the right butterfly valve, you need to pay attention to specific features. The design of the valve is crucial. Some have a lightweight build, making installation easy. Others are more robust, ideal for demanding applications. Ensuring the right fit for your system is vital for optimal performance.

Different models offer various materials. Some use durable metal; others opt for plastic. Each material presents unique benefits. For example, stainless steel may resist corrosion, while plastic offers cost-effectiveness. There's a balance between budget and longevity that needs careful consideration.

It's important to read reviews before making a choice. Users often share insights on performance. Some valves work flawlessly, yet others might leak or jam. Not every model performs as claimed. You may need to explore several options to find the best fit. Pay attention to warranties too; they reflect a manufacturer's confidence in their product.

Comparative Analysis of Brands: Best Choices for 2026

When searching for the best butterfly valves in 2026, it's important to consider various brands. Different designs and materials can drastically affect performance. Some valves are made from stainless steel, while others use ductile iron. Each material has distinct advantages. However, the choice may lead to confusion.

In comparing top brands, focus on functionality and durability. Not all valves perform equally. Some may leak under pressure, while others resist corrosion. This leads enthusiasts to wonder about reliability. Customers often overlook maintenance requirements, which can impact long-term use. Recommendations sometimes lack clarity on customer experiences, raising questions about the necessary specifications for diverse applications.

Also, price ranges differ significantly. Higher costs don’t always ensure better quality. Value is subjective, influenced by specific use cases. Buyers may feel pressured to justify their choices. Reading user reviews can provide insight, but opinions vary widely. This makes it necessary to consider various perspectives. Ultimately, making an informed decision in the crowded butterfly valve market requires careful thought and thorough research.

Maintenance Tips for Butterfly Valves to Ensure Longevity

Maintaining butterfly valves is crucial for their longevity and performance. Regular checks can prevent major issues. Dirty valves may stick, leading to costly repairs. Inspect the valve exterior for signs of wear. Dust and grime can build up, affecting functionality. A simple cleaning can extend its life significantly.

Lubrication is vital too. Use the right type of lubricant to avoid corrosion. Over-lubrication can be as harmful as under-lubrication. Check seals regularly; worn seals cause leaks. A small leak might seem harmless, but it can lead to bigger problems. Replace damaged seals promptly to maintain optimal performance.

Temperature fluctuations can also affect valve efficiency. Extreme conditions may warp materials. Ensure the operating environment is stable when possible. Regularly monitoring performance can catch potential issues early. Take time to assess the valve's operation periodically. Making adjustments as needed can save time and money in the long run.

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES